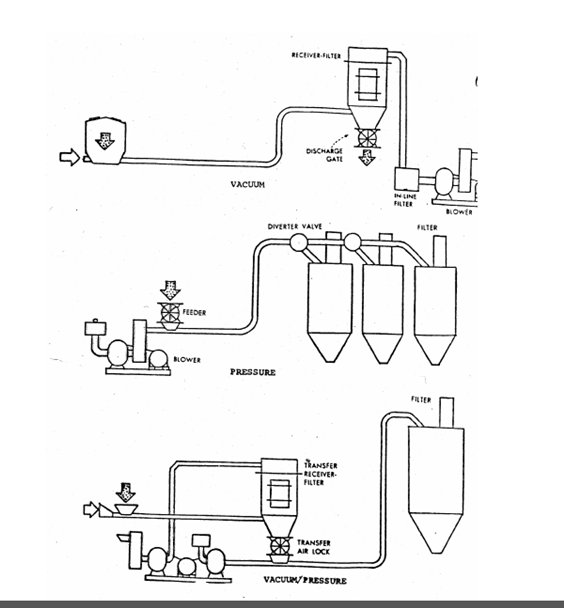

| Systems and Modes |

| |

| Pneumatic Conveying Systems |

| |

|

| |

| The dilute phase mode of transport is the most common in pneumatic conveying applications. Older designs mostly used excessive air hoping to eliminate operational problems. Such systems consumed too much energy and lead to pipe wear and particle erosion and degradation. Keeping the air flow at a minimum above the saltation velocity is the optimum point of operation to save energy.

|

| |

Dilute Phase (Stream Flow)

- High air to material ratio

- Material remains in suspension above saltation

- Cooling and drying during conveying

- Higher velocities

- More abrasion and breakage

|

| |

| Dense phase conveying systems were introduced commercially in the early 1970s and were thought to be the answer to a maidenís prayer in the conveying world. Lower air velocities eliminated the need to be above the saltation velocity as well as cut down on the amount of particle breakage and pipe erosion. These objectives have been achieved but the operation of the dense phase system can be problematic since does have more unstable flow situations that can occur. There are many unique designs for dense phase systems devised by various manufacturers with a wide range of pricing.

Dense phase is an ill-defined word in itself and can represent a wide variation in the flow condition from dune type flows to moving piston flow. These systems in general operate at higher pressures than the dilute phase flow systems.

|

| |

Two Phase (Dense Phase)

- Moderate air to material ratio

- Stream flow over salted bed

- Lower velocities

Dense Phase (Plug Flow and Extrusion Flow)

- Pistoms formed and moved by differential pressure

- Low air volume

- Higher air pressure

|

| |

| A force balance can be written on the pipe or pipe section utilizing the various forces

that act on the particles in transport. The balance of forces is obtained by summing up the drag and external forces in the longitudinal direction and noting the gravitational force in the vertical direction.

|

| |

| |